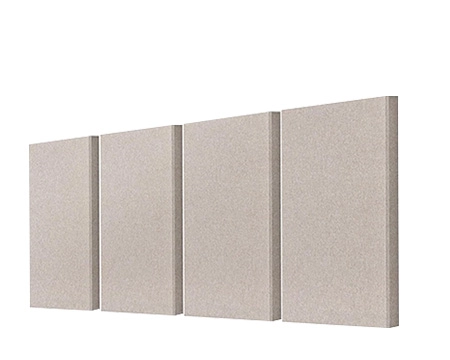

Acoustic Ceiling Panels

Acoustic Control: Employee surveys showed 68% productivity loss due to noise distraction,Thermal Management: HVAC systems overworked compensating for poor insulation

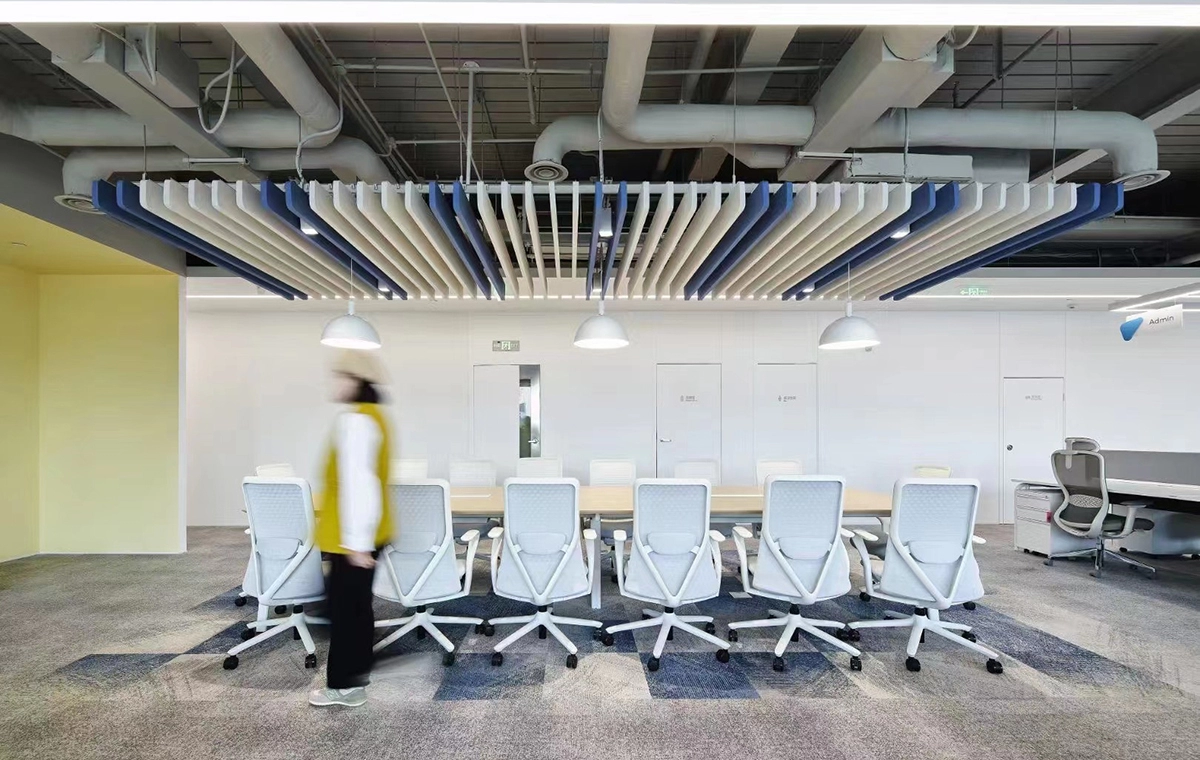

Case Study: Acoustic and Sustainability Transformation in Fortune 500 Workspace

Solution: Roydaa PET Felt Ceiling System

Scope: 15,000 sq ft Corporate Innovation Hub

Verified Outcomes:

0.51s reverberation time (68% reduction from baseline)

42% decrease in HVAC energy consumption

100% recycled material utilization

Challenge: Integrated Performance Demands

A global technology corporation required ceiling solutions addressing three critical needs:

Acoustic Control: Employee surveys showed 68% productivity loss due to noise distraction

Thermal Management: HVAC systems overworked compensating for poor insulation

Sustainability Compliance: LEED v4.1 Platinum target requiring Cradle-to-Cradle certification

Solution: Engineered PET Ceiling System

Installation:

2,200 custom panels across three zones:

Collaborative Labs: 20mm Hexagonal (NRC 0.93)

Focus Areas: 30mm Cloud Profile (NRC 0.95)

Atrium: 40mm Waveform (NRC 0.97)

Technical Specifications:

Material: 100% post-consumer recycled PET felt

Fire Safety: Class B

Integration: Pre-engineered cuts for lighting/sprinklers

Performance Validation

Qualitative Outcomes:

36% reduction in employee fatigue reports

Zero maintenance interventions in 12 months

en

en en

en