With the rise of prefabricated buildings, acoustic panels have ushered in new opportunities

The global construction industry is undergoing a radical transformation with the rapid adoption of prefabricated building techniques. As modular construction becomes mainstream—projected to comprise 30% of new buildings by 2028—the demand for prefabricated acoustic walls and ceilings has skyrocketed. Unlike traditional builds, prefabrication demands materials that are lightweight, easy to install, and adaptable to standardized systems, creating both opportunities and challenges for acoustic panel manufacturers.

Why Prefabrication is Reshaping Acoustic Design

Prefabricated construction prioritizes speed, cost efficiency, and sustainability, requiring acoustic solutions that align with these goals. Key industry shifts include:

Lightweight Materials: Heavy traditional panels (e.g., concrete or dense fiberboards) are being replaced by composite materials like aluminum foam or aerogel-infused boards, which offer comparable noise reduction (STC 50+) at half the weight.

Modular Integration: Leading companies like Knauf and USG now offer clip-in acoustic panels that seamlessly integrate with prefab wall/ceiling systems, reducing on-site labor by up to 40%.

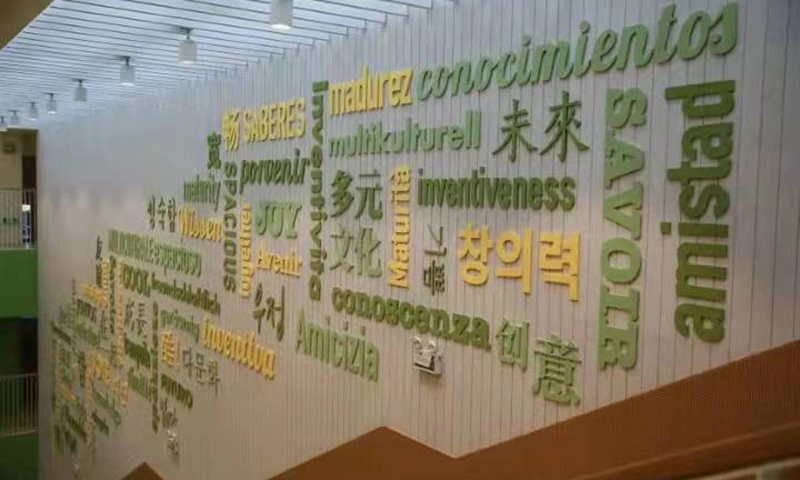

Design Flexibility: Open-plan offices and mixed-use spaces require reconfigurable acoustic solutions. For example, demountable partition walls with embedded sound-absorbing cores are gaining traction in commercial projects.

Innovations Driving the Market

To meet prefabrication demands, manufacturers are pioneering:

Plug-and-Play Acoustic Modules: Panels with pre-installed gaskets and interlocking edges (e.g., Armstrong’s TechZone™) enable tool-free installation.

Hybrid Performance Materials: Products like 3D-printed acoustic tiles combine PLA (polylactic acid) with recycled textiles for tunable sound absorption (NRC 0.6–0.95).

BIM-Compatible Systems: Digital twins of acoustic panels allow precise prefab planning, minimizing waste. For instance, Saint-Gobain’s Ecophon™ provides BIM files with detailed dB reduction simulations.

Challenges and Solutions

While prefabrication accelerates timelines, it introduces new hurdles for acoustics:

Air Tightness: Joints between modules can compromise sound insulation. Solutions include compression seals and resilient channels.

Fire Compliance: Lightweight materials must still meet Class A fire ratings. Manufacturers are testing ceramic-coated mineral wool panels to balance safety and weight.

Cost Barriers: High-performance modular systems can be 15–20% pricier than traditional options. Economies of scale (e.g., China’s BYD modular housing projects) are helping reduce costs.

Strategic Recommendations for Suppliers

To capitalize on this $12 billion prefab acoustics market (Grand View Research, 2023), companies should:

Collaborate with modular builders early in the design phase to customize solutions.

Invest in R&D for multi-functional panels (e.g., structural + acoustic).

Adopt circular design—modular panels should be reusable across multiple building lifecycles.

Conclusion

The prefabricated construction revolution is unstoppable, and acoustic panel manufacturers must evolve or risk obsolescence. By prioritizing lightweight innovation, digital integration, and sustainability, the industry can turn these challenges into a competitive edge—ensuring soundscapes keep pace with the speed of modern building.

en

en it

it es

es hu

hu ja

ja sv

sv pt

pt ms

ms ko

ko ru

ru fr

fr de

de ar

ar